Triple Wall PC Sheet

Brand:YSD

Raw material:Sabic polycarbonate resin

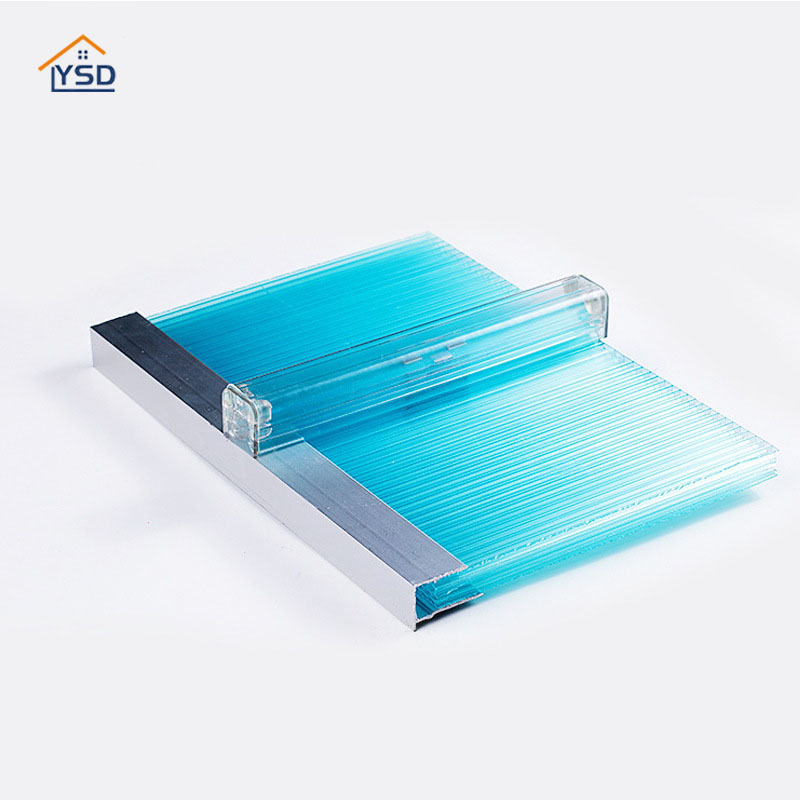

Thickness:8mm / 10mm / 12mm / 14mm / 16mm

Width:1.22m, 2.1m, Max 2.17m, and others cut to size

Length:2.44m, 5.8m, 11.8m and other lengths customized

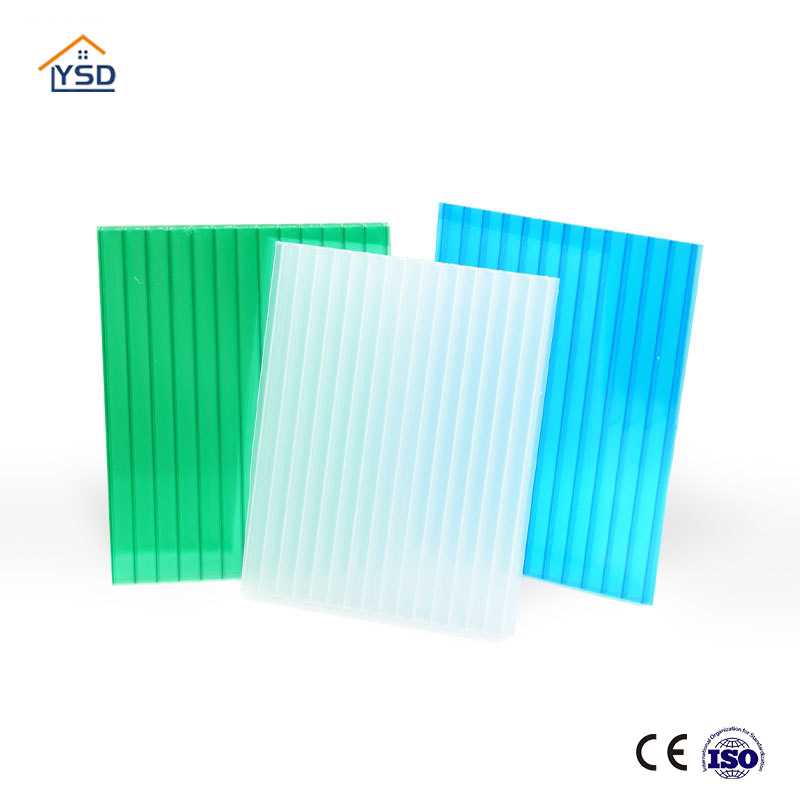

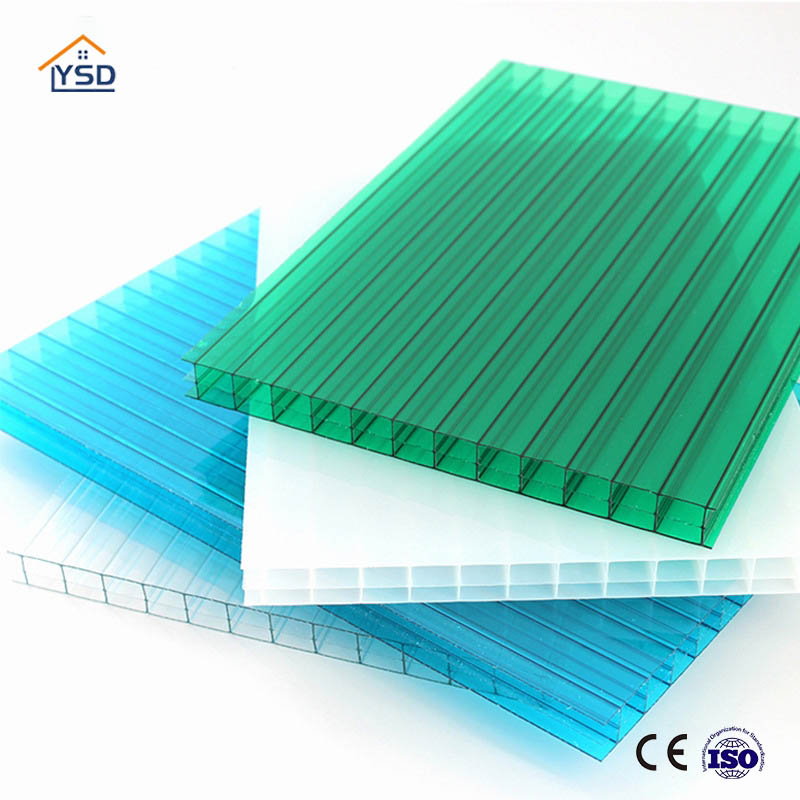

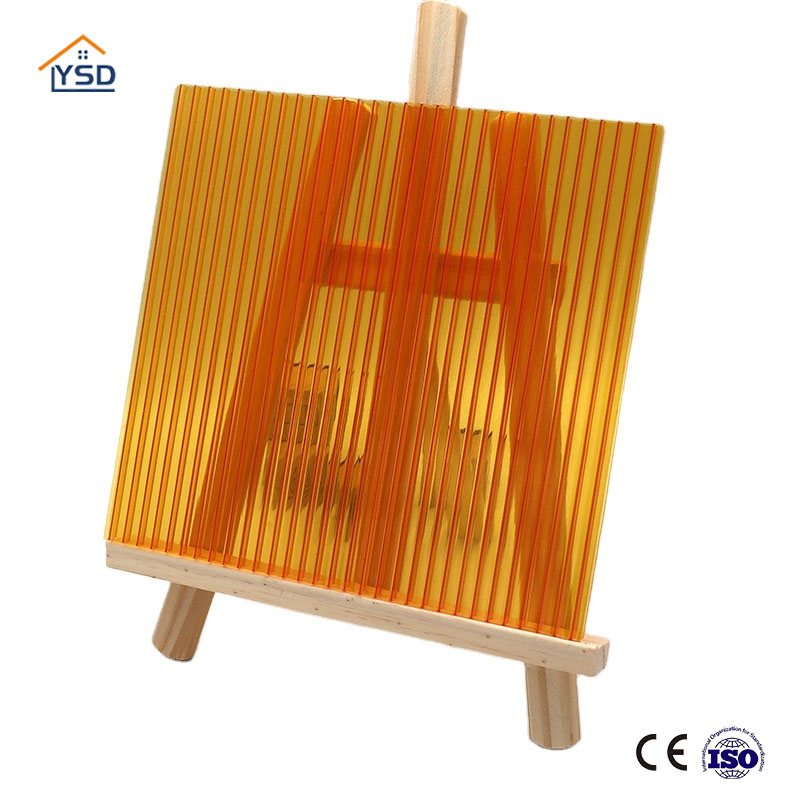

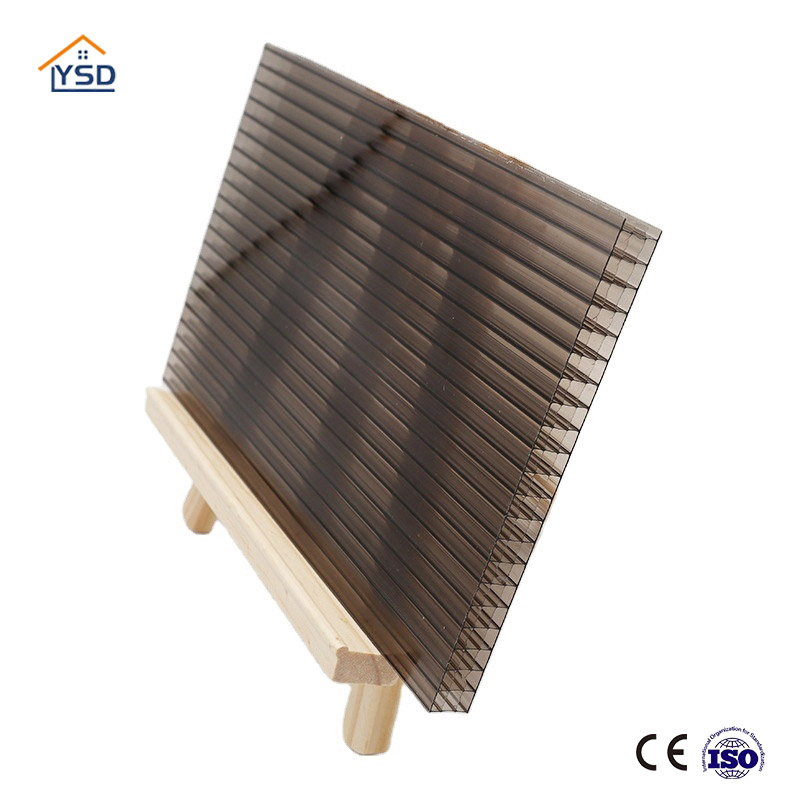

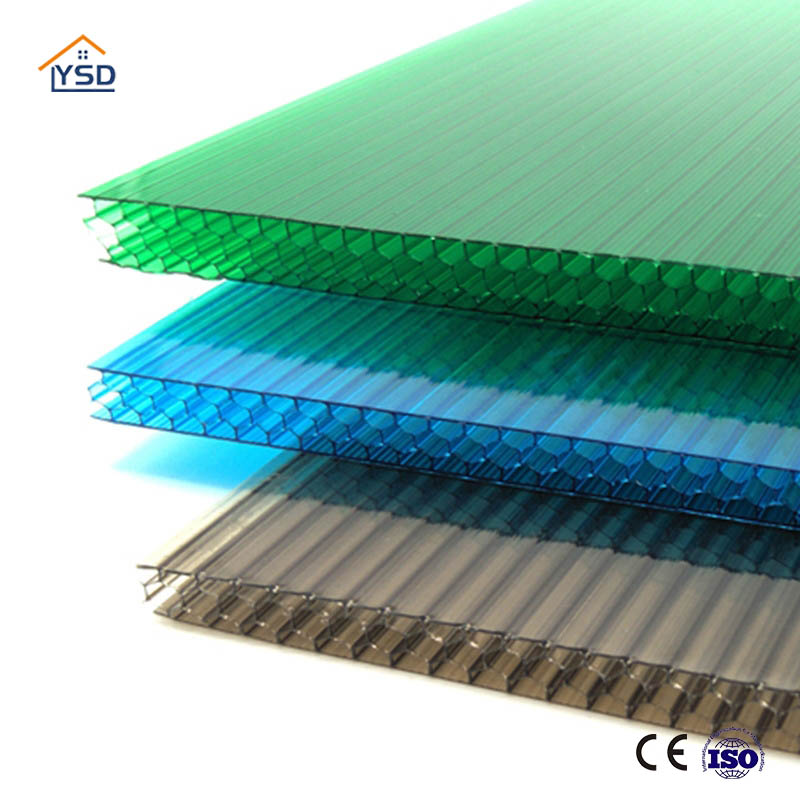

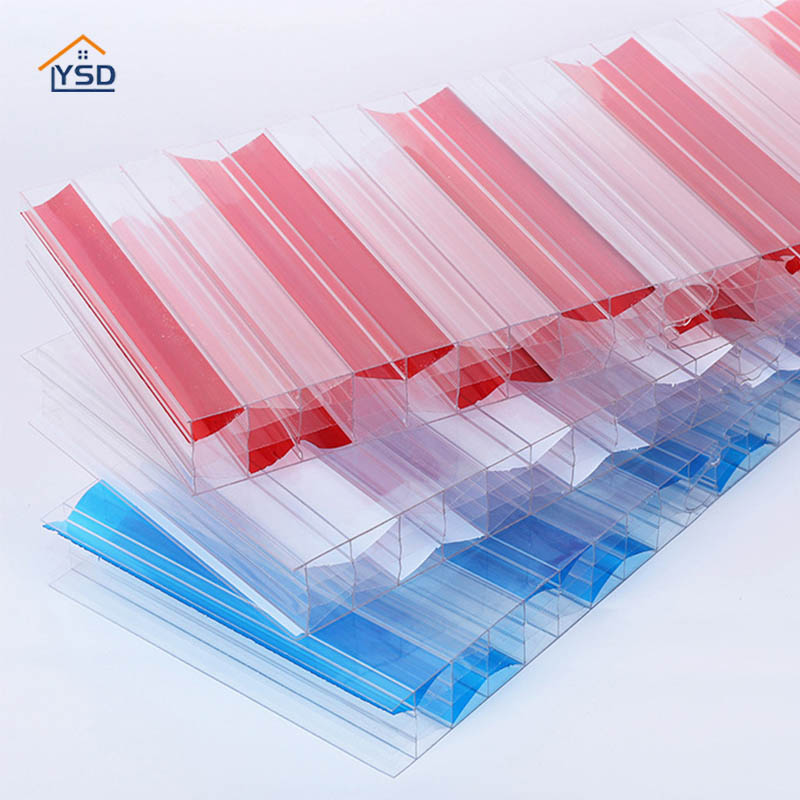

Color:clear, bronze, opal, smoke, gray, blue, grass green, red and other customized colors

UV coated:50um uv coated on one side and two sides.

MOQ:300 square meters

Customization:logo film for free when order 40ft HQ container.

Surface treatment:crystal, UV coating, anti-fog.

Send Inquiry

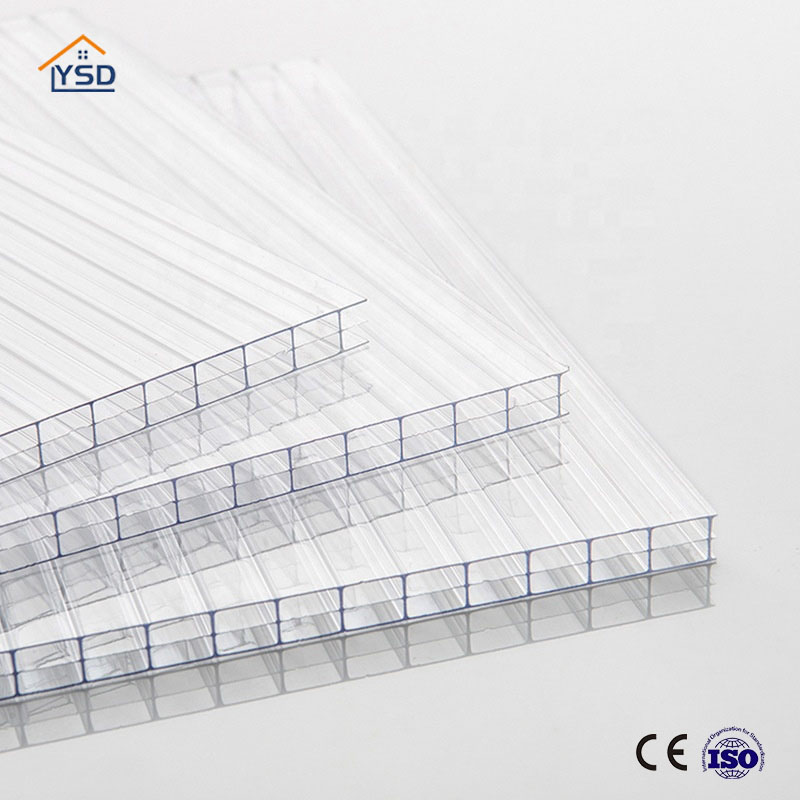

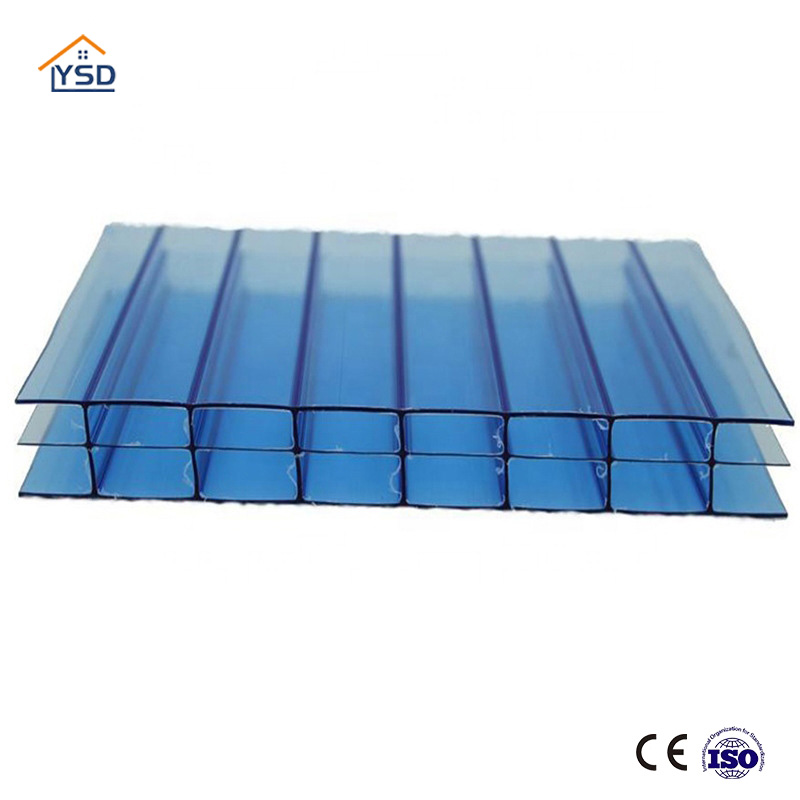

Triple wall polycarbonate sheet, as the name suggests, has three layers of wall. Compared with twin wall polycarbonate sheet, triple wall PC sheet is much strong and heavier than that of twin wall PC sheet. If you request much stronger but with lower cost, triple wall polycarbonate sheet is your best choice. It is widely used for outdoor curtain wall, plastic roofing, office partition and other usages.

Triple Wall Polycarbonate Sheet | |||||

Thickness | Weight(kg/m2) | Standard K Value(W/m2k) | UV coating | Light Transmittance | Minimum Bending Radius |

8mm | 1.70 | 2.92 | 50um | 71% | 1400 |

10mm | 2.00 | 2.68 | 50um | 70% | 1750 |

12mm | 2.20 | 2.60 | 50um | 69% | 2100 |

14mm | 2.40 | 2.42 | 50um | 68% | 2450 |

16mm | 2.60 | 2.27 | 50um | 67% | 2800 |

-- Loading Capacity Reference

Thickness | Loading Capacity | ||

20ft | 40ft GP | 40ft HQ | |

8mm | 298 pcs | 596 pcs | 698 pcs |

10mm | 240 pcs | 480 pcs | 560 pcs |

12mm | 199 pcs | 398 pcs | 464 pcs |

14mm | 170 pcs | 340 pcs | 398 pcs |

16mm | 149 pcs | 298 pcs | 348 pcs |

More for details, pls contact us. | |||

1.Light weight: its weight is one-twelfth of glass of the same thickness;

2.Super impact resistance: the impact strength is 350 times that of ordinary glass, 35 times that of acrylic plate, and 2 times that of tempered glass;

3.Energy saving: low heat transfer coefficient (K value), good heat insulation, energy saving is 1.5-1.7 times of the same thickness of glass;

4.Weather resistance: artificial climate aging test 4000 hours, yellowness degree is 2, light transmittance reduction value is only 0.6%;

5.Wide range of use: between -40 °C ~ 120 °C, stable physical properties, no deformation of the sun panel;

6.Cold bending: can be cold bending, the safe bending radius is more than 175 times of its plate thickness;

7.Flame resistance: tested by the National Fireproof Building Materials Quality Supervision and Inspection Center, the burning performance of the solar panels produced by the company has reached flame retardant B1 grade;

8.Anti-coagulation: one side can be used as anti-condensation treatment to prevent condensate dripping;

9.Sound insulation: polycarbonate sheet has good sound insulation performance and can effectively reduce noise;

10.UV layer: the board surface is added with UV anti-ultraviolet layer to extend the life of the board;

11.Wind resistance: The wind resistance performance reaches the first level of the national standard GB/T7106-86.

Ø We promise that we use real Polycarbonate Resin, no other plastic material such as PS;

Ø We use 100% virgin PC material, refuse recycled material;

Ø Rich experience for export business. So our colors can be almost the same with your samples, and many colors for your choice.

Ø UV coated can be averagely tinted on the polycarbonate sheet;

Related products

I Want

-

Need to assist with product selection

Chat online

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.